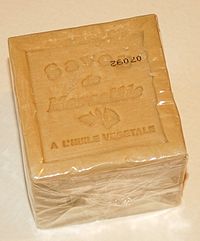

Introduction to soapmaking Soap making is an age-old skill that is currently undergoing a popular revival. Many people are discovering how much fun it can be to make soap. Using our free online guide you will experience the satisfaction of making your own luxurious, moisturizing, and non-irritating soap using inexpensive ingredients that are easy to obtain. Learning to make your own soap can be a rewarding and worthwhile experience. Not only does it teach a valuable skill but it is also a great deal of fun. It is abundantly rewarding to use a product that you have made yourself and the feeling of self reliance is a very good feeling. How Soap is Made Soap is made by mixing lye and water with fats or oil. Through a complex chemical reaction lye which is also called sodium hydroxide (a base) converts Fats or Oil (an acid) to soap. This process is called saponification. When oil or fats (acid) come into contact with the lye or sodium hydroxide (base) the saponification process begins with the lye turning the oil/fat into a completely new substance that we know as soap. The process changes the two substances into a thicker and more uniform solution. The point at which the solution begins to thicken is called a trace. Any oils/fats or other ingredients added at this point will not be substantially converted and will basically remain in the soap in their original form. At the trace stage the soap can be poured into molds where it will continue to harden. The chemical reaction will continue for about 3 weeks at which time the soap is hard and ready to use. The process that the home soapmaker will use is referred to as "cold process soapmaking". Even though it is called a cold process, heat is required for the chain reaction to take place. This heat is provided by the chain reaction of the water and the lye and their incorporation into the oil or fat. (You will notice that when the lye is poured into the water it heats up immediately) Stirring the oil/fat/lye mixture helps this process to continue and to be uniform. How Soap Cleans Soap cleans by acting as an agent between water and dirt. Soap allows the water to wet the surface that is being cleaned better. For example, you have heard of water off a ducks back. Soapy water tends to soak into the surface being cleaned therefore allowing the water to wash away dirt. In addition, soap grabs dirt and connects it to the water. Soap basically grabs dirt or grease and allow water in to wash it away. This may be an over simplification of the process but it is accurate. Soap does more than just clean. The soap you make using this online guide will contain at least 25% pure glycerin. Glycerin draws moisture to the skin, soothing and lubricating it's cells. Most soap sold in stores has had it's glycerin removed and sold back to the consumer in other skin care products. Also, most store soaps are actually petrochemical-based detergents, which are good cleansers but are harsh on the skin. Lye soap has been around for quite a while for one major reason; it's simple and it works. When properly made it has some wonderful characteristics. Here are some of those characteristics as well as some other good reasons to make your own soap : example of a self made soap

| diagram on soap mixing

History

Early history

The earliest recorded evidence of the production of soap-like materials dates back to around 2800 BC in Ancient Babylon.[1] A formula for soap consisting of water, alkali and cassia oil was written on a Babylonian clay tablet around 2200 BC. The Ebers papyrus ( [Roman history

It had been reported that a factory producing soap-like substances was found in the ruins of Pompeii (AD 79). However, this has proven to be a misinterpretation of the survival of some soapy mineral substance,[citation needed] probably soapstone at the Fullonica where it was used for dressing recently cleansed textiles. Unfortunately this error has been repeated widely and can be found in otherwise reputable texts on soap history. The ancient Romans were generally ignorant of soap's detergent properties, and made use of the strigil to scrape dirt and sweat from the body. The word "soap" (Latin sapo) appears first in a European language in Pliny the Elder's Historia Naturalis, which discusses the manufacture of soap from tallow and ashes, but the only use he mentions for it is as a pomade for hair; he mentions rather disapprovingly that among the Gauls and Germans men are likelier to use it than women.[2] A story encountered in some places claims that soap takes its name from a supposed "Mount Sapo" where ancient Romans sacrificed animals. Rain would send a mix of animal tallow and wood ash down the mountain and into the clay soil on the banks of the Tiber. Eventually, women noticed that it was easier to clean clothes with this "soap". The location of Galen describes soap making using causticised lye and prescribes washing to carry away impurities from the body and clothes[3]. The best soap was German according to Galen; soap from Zosimos of Panopolis c. 300AD describes both soap and soap making.[4] Muslim history

True soaps made from vegetable oils (such as olive oil), aromatic oils (such as thyme oil) and lye (al-Soda al-Kawia) were first produced by Muslim chemists in the medieval Islamic world.[5] The formula for soap used since then hasn't changed. From the beginning of the 7th century, soap was produced in In semi-modern times soap was made by mixing animal fats with lye. Because of the caustic lye, this was a dangerous procedure (perhaps more dangerous than any present-day home activities) which could result in serious chemical burns or even blindness. Before commercially-produced lye (sodium hydroxide) was commonplace, potash, potassium hydroxide, was produced at home from the ashes of a hardwood fire. This are just tips, i have the full version with me that can teach you on how to become you own boss, be under your self and not sayiny yes sir for any body, through soap making. if you really want the book and the video cd that will guide you through this processs simply text or call this number. 08058753880 or e-mail me to the following addresses: samabans@gmail.com or samabans@yahoomail.com or samabans@rocketmail.com. you are welcome thanks for visiting my site. i am femi akanbi |